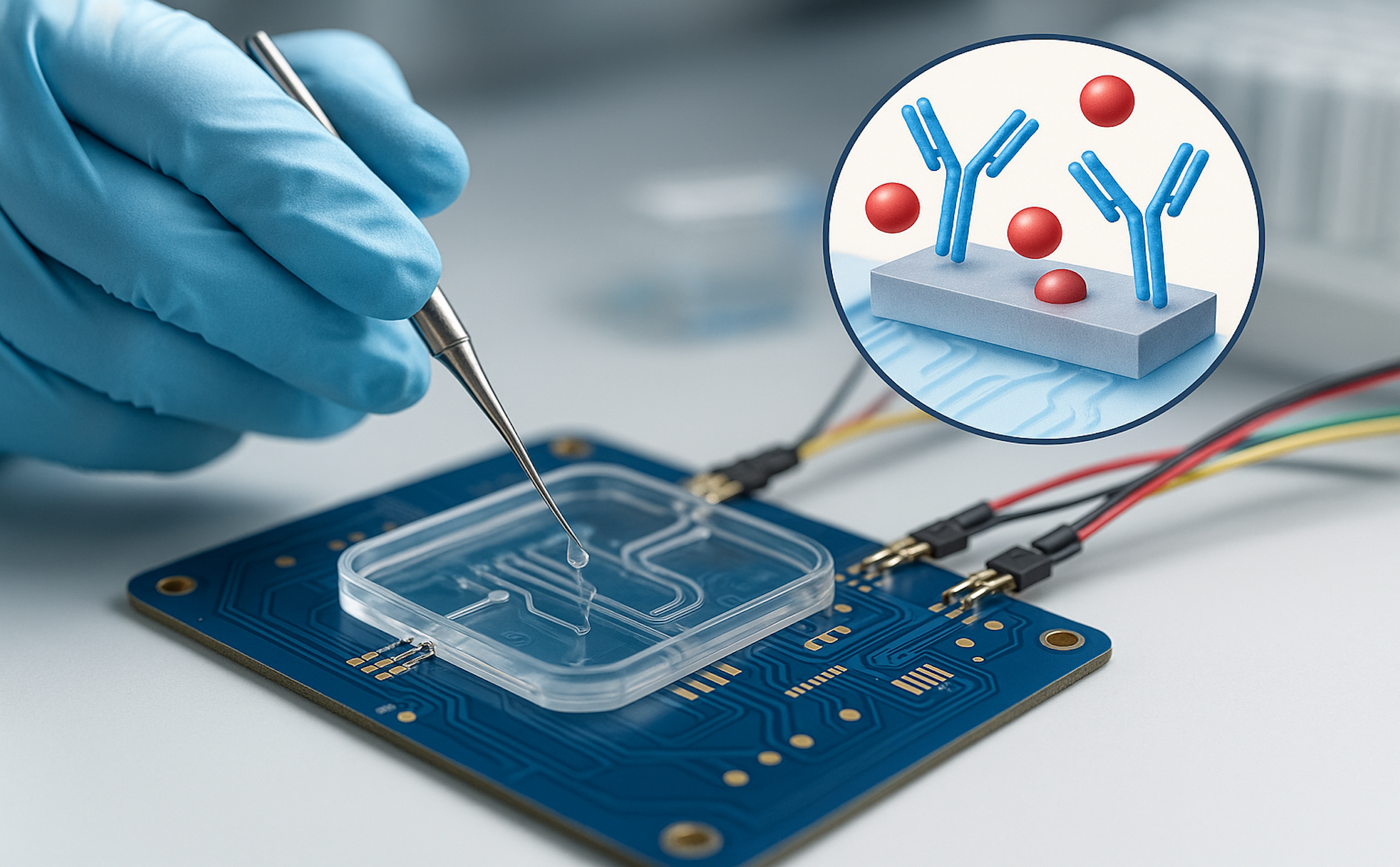

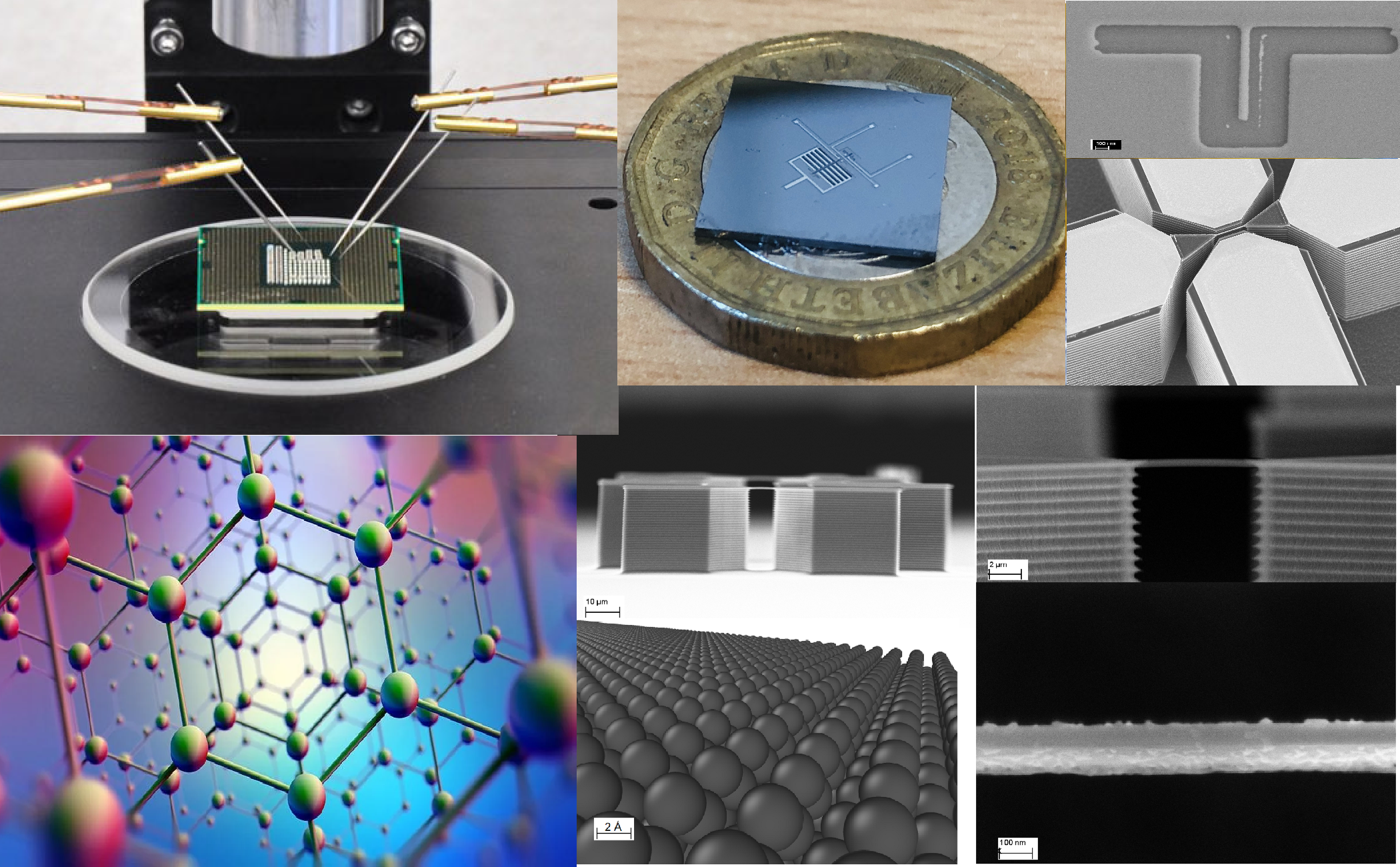

Biosensors and chemical sensors enable high resolution detections for digital healthcare and environmental monitoring applications. These sensors are typically developed under ideal laboratory conditions using homogeneous samples, resulting in optimal sensor performance. However, in clinical settings, the presence of complex buffer matrices and variability in sample composition introduces significant "noise," which can compromise the reliability and effectiveness of these sensors. Our perception on molecular binding interaction is one key challenge to fully characterise sensors (link). This project aims to build new guidelines based on developing novel multiscale approaches to understand binding kinetics and inform microfluidic technologies for the development of fast and reliable measurement techniques, tackling challenges associated with current technologies.